Precision Machining for LabTech

medical

devices

medical

devices

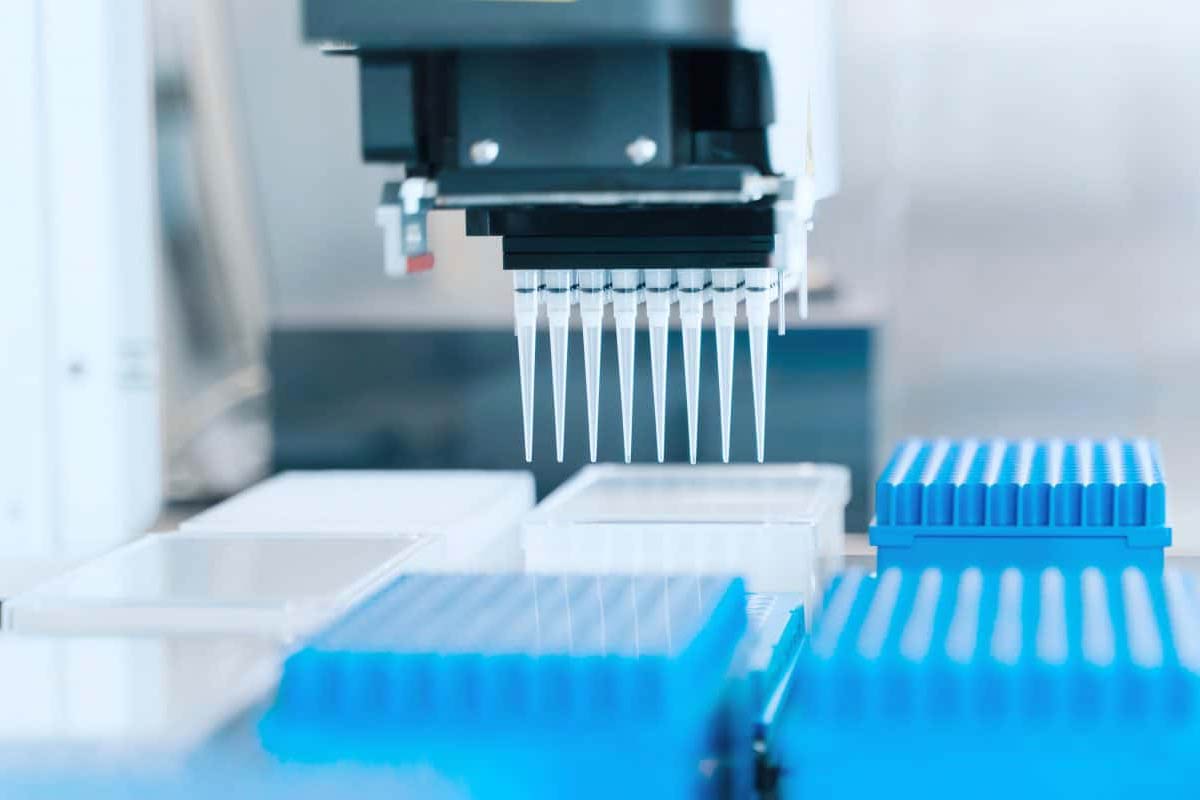

CNC machining, milling, and turning processes are used to produce a wide array of components for laboratory equipment that fall under the general umbrella of laboratory technology. Whether they are used in research labs, educational or medical labs for analyses and diagnostic testing, these parts are characterized by tight tolerances, extremely fine surface finishes, cleanliness and the ability to withstand varying chemical influences.

On the other hand, contrary to other medical equipment like surgical instruments and dental and orthopedic implants, laboratory instruments and their components rarely come into direct lengthy contact with human tissues and therefore need not be biocompatible. This opens up multiple material options that can be considered for production through CNC machining.

As specialists in precision machining, at Décovi we routinely produce various components for laboratory equipment from miniature sized sampling and testing instruments to larger parts for more complex medical, such as hydrogen generators or medical imaging and diagnostics.

Machined laboratory equipment parts can include:

The parts we machine can be small components like screws, cutters, connectors, switches, buttons and levers, mixers and larger items such as electrodes and housings.