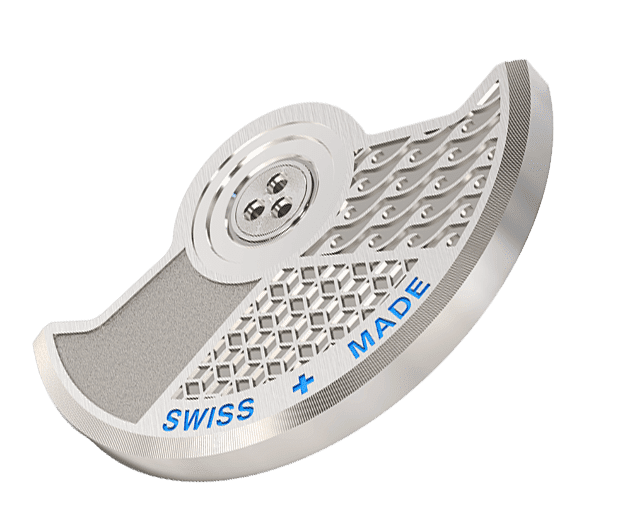

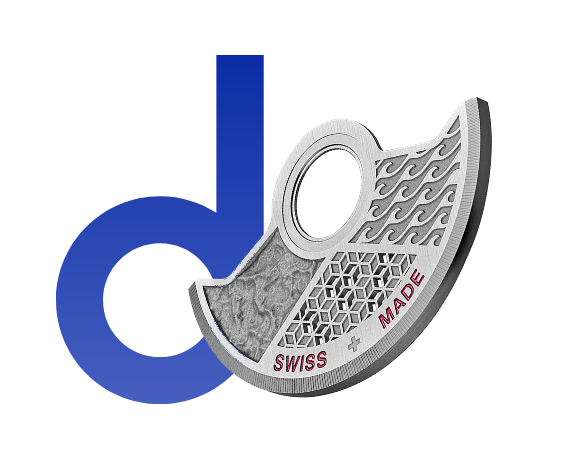

Décovi at SIAMS 2024 with Acrotec Group !

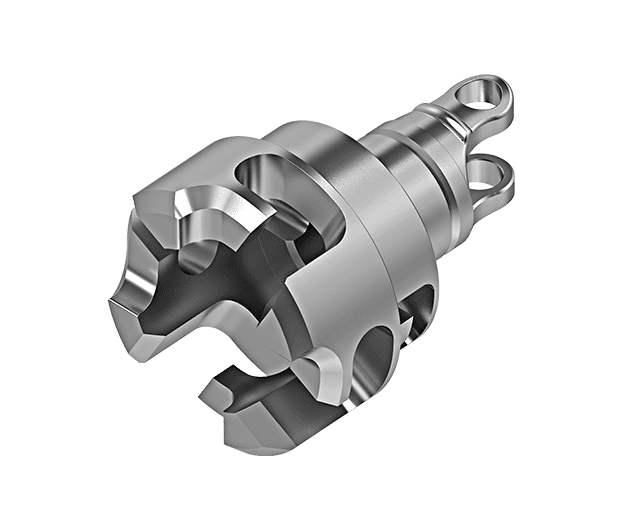

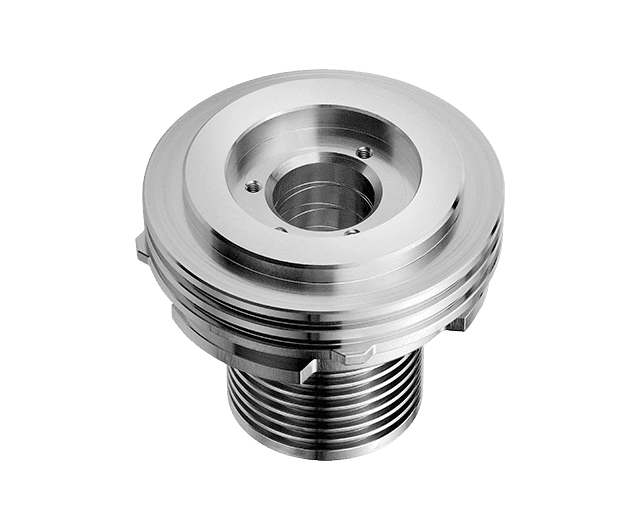

Get ready to discover Microtechnology excellence With the key microtechnology event fast approaching, the Acrotec Group is gearing up to shine at SIAMS 2024, to be held in Moutier from April 16 to 19. Seven Group companies – AFT Micromécanique, Décovi, easyDec, Petitpierre, STS Develier, Tectri and WatchDec – will be showcasing Swiss innovation and expertise. SIAMS in brief: Located in the heart of…