Decorations in Watchmaking

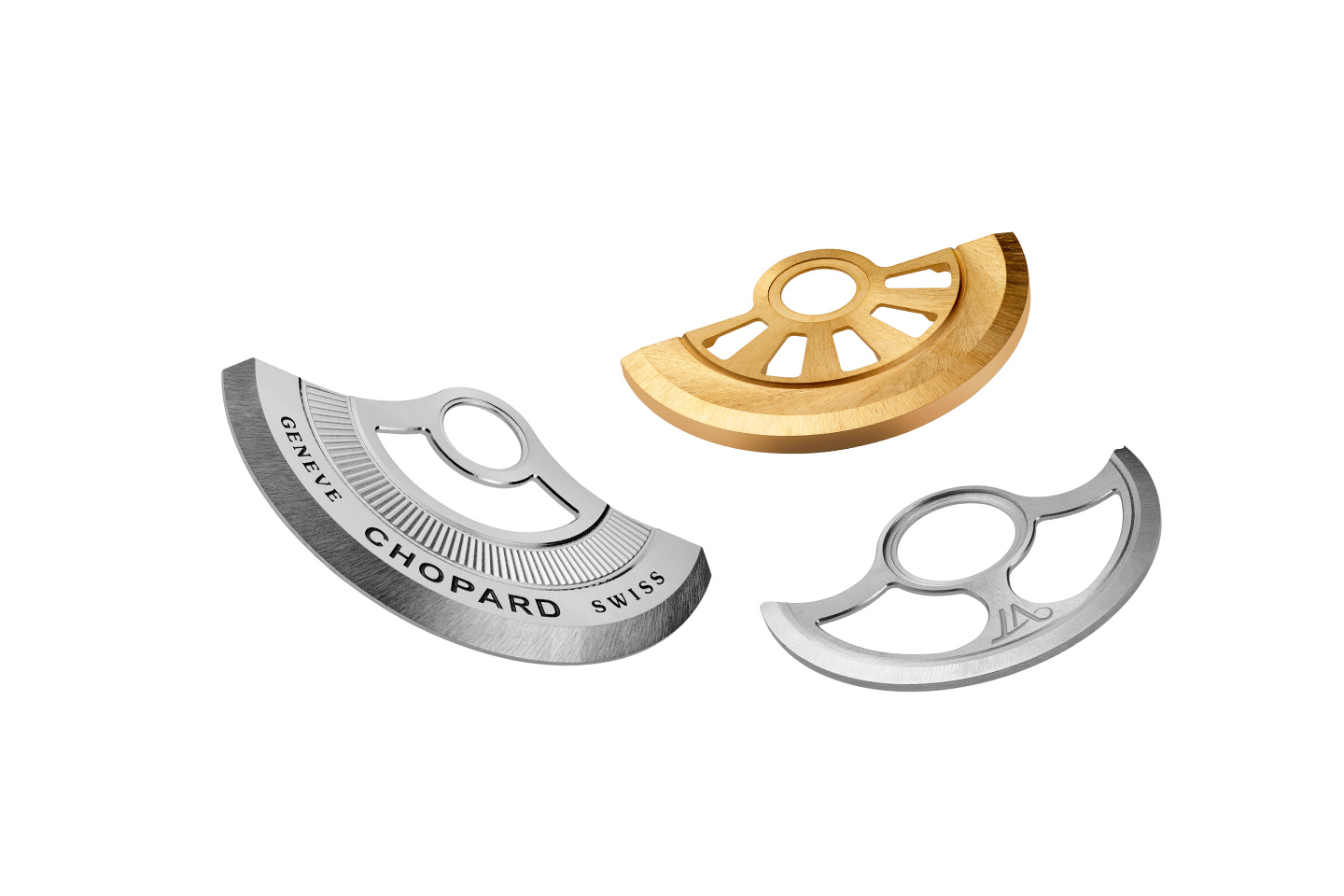

Our expertise in the execution of decorations and fine finishings makes us a trusted partner to many renowned watchmakers and suppliers of watch components.

Different types of decorations and finishings are widely used in watchmaking for aesthetic but also for functional reasons. Some finishings improve durability and accuracy of the product, while others are used by renowned watchmakers exclusively as their brand’s distinctive marks.

Decorations are usually made with advanced high-precision machines.

We realize many types of decorations:

- Côtes de Genève

- Circular graining

- Snail

- Sunlight

- Satin-finishing

- Strapping

We also carry out sawing, pad printing and colouring operations on our parts, as well as various surface treatments.

Most Common Types of Decorations

Côte de Genève (or Geneva stripes)

This is probably the most famous decorative technique for watches, besides engraving and polishing. Once a signature sign of Swiss watchmaking, this type of decoration is today used by watchmakers world-wide.

It consists of regular parallel wave-like lines or stripes achieved with an abrasive tool, and is mostly used on the visible surface of bridges and the oscillating weight.

Satin-finishing

Satin-finishing is done by engraving a metal surface with a series of extremely fine, uniform and impeccably parallel stripes.

Circular Graining

Circular Graining is achieved with the same technique as satin finish, only here the fine parallel lines are circular.

Sunlight brushing & Snailing

Sunray brushing also involves decorating a surface with straight lines running from the centre to the edge of the piece, much like the Sun’s rays.